Most of us car guys are just amateur shade tree mechanics, relegated to simple R&R (remove and replace) operations at best. But then, Scott Reid is no shade tree mechanic. Scott, founder and President of Miur Essence, has been modifying and enhancing automobiles since he was a kid in high school. His latest (and likely grandest) achievement has been the design, development, and implementation of a series of major engine enhancements for the Lamborghini Miura.. a car long recognized as the world’s first “Super Car”. Scott’s engineering achievements for this car would make even the most accomplished Formula One technician team take notice!

Scott’s story begins some 6 decades ago: According to him he remembers being fascinated with automobiles from the age of 2! His first engine rebuild was a Briggs & Stratton lawnmower engine at the age of 13. Even as a high schooler he had an unquenchable interest in anything and everything mechanical. One of his first cars was a 1940 Ford, acquired at the age of 15.

Scott earned his informal mechanic’s credentials during high school working on that ’40 Ford. He completely revamped the car’s running gear, including different rear end, and installation of a 400HP (estimated) Chevy 327 and 4 speed transmission.

Scott enjoyed terrorizing the neighborhood during his high school years, and the car piqued his interest in drag racing where he was a regular at the strips around Dallas-Fort Worth..

Throughout college and afterward, Scott’s face was a familiar one at drag strips all around Texas and beyond, as he campaigned his then-owned and modified 1963 Corvette.

What changed it all was a college-age trip to the local Glastron boat factory, located in Austin, where he was given a marketing poster for the company. The poster was a huge photo of one of their boats. But Scott’s eyes never saw the boat, because figured prominently in the same photo was a beautiful Lamborghini Miura. At that moment, Scott just knew that some day he would have to own one of those cars.

The old and the new. Scott’s Lamborghini on the right, overshadowing a new Lambo Aventador on the left

The Miura, one of the very first mid-engined road cars, was produced at the Lamborghini factory in Italy between 1966-1972. An estimated 474 P400 Miuras were manufactured between 1966 and 1969. The car was immediately hailed as an engineering and design tour de force, and after figuring prominently in the opening sequence of The Italian Job movie, the car became the stuff of dreams for millions of gearheads worldwide. Scott was no exception, and swore he would own one someday.

Alas, the cost of a new Miura (about 5 times the cost of a new Corvette) was light years away from the budget of a struggling college student, and those dreams of a Miura had to be put on the shelf in favor of a new career as an engineer at IBM.

During those post-college years, Scott kept himself distracted from thoughts of that Miura by engaging in an active drag racing hobby, trailering his 1963 Corvette all over the country in pursuit of yet another trophy.

Finally, in 1981, Scott realized that continuing to pour money into drag racing was a one-way trip to financial disaster. In addition to the ’63 Vette, he had also picked up a ’56 Vette. He began to do the math, and discovered that if he were to sell both of those Corvettes, and add roughly an equal amount in cash, he might just barely be able to pay for that Miura of his dreams. In the ensuing months, he looked at several for-sale Miuras around the country, but none quite measured up to his scrutiny until he learned of a beautiful silver Miura being offered for sale at a dealer on the West Coast. Scott and his wife Tricia flew out to inspect the Miura, and negotiated a deal on the spot. Scott, of course, could never have dreamed that the price which seemed so outrageous in 1981 would be a pittance compared to today’s vaules, which, routinely exceed the 7 figure range!

Like any true gearhead, Scott decided that driving the car home (some 1,800 miles) was preferable to having it shipped. The drive from Berkeley, California to Austin turned out to be an adventure that could be the basis of another full story on its own, but suffice to say that to get the car to Austin consumed some 24 quarts of oil (due to a leaky oil sender, discovered only after the trip was complete), and rendered all 4 tires completely bald (due to bad suspension misalignment). Nevertheless the Miura DID make it to Austin on its own power, and has resided in the Scott garage ever since.

The Miura rests in Scott and Tricia’s residential garage

That beautiful transverse mounted Lamborghini V12 engine. Che Bella Macchina!

Fast forward to current times… For the past 30 years or so, the Miura has sat quietly in Scott’s garage, admired and cherished, but frequently ignored, in favor of raising a family, and devoting time to a successful engineering career at IBM. Of course, it wasn’t all work and no play, as Scott did find time to build a quarter midget racer in support of his sons’ interest in the sport (that car now hangs from the ceiling of the Scott’s family room!)

Quarter Midget racer built for Scott’s sons, hangs in the family room!

Additionally, Scott did find time to design and construct a serious off-road “vehicle”, a near-finished project that will be on the (off) road soon.

But, a couple of years ago Scott was able to hang up his IBM badge for the last time, and transition to a not-full-time-employed status. Scott had long had a lengthy bucket list of problems and issues with the Miura that he was itching to solve. These issues were not specific to his own car, rather they were deficiencies in the entire model production, and had gone unresolved over the years.

The technical aspects of the Miura’s engine and transaxle most likely win the crown in the most-complex-and-unconventional design department. Unfortunately, some of the unconventional aspects of that big beautiful V12 engine created operational and driveability problems.

The most egregious complaint was the design in which the engine and transaxle shared a common lubrication sump. Not only did this necessitate a compromise recommended oil viscosity (per Lamborghini… 50wt oil..really thicker than optimum for the engine, yet thinner than optimum for the transaxle), but the shared sump invited transfer of foreign particles from one component to another.

Additionally, the very shallow engine sump/oil pan, necessary because of the extremely low profile of the car, could not contain enough oil to prevent oil starvation during hard cornering, essentially endangering the engine’s health.

Undaunted by the ‘mere’ complexity of these mechanical components, Scott outfitted his sizable garage with the latest in fabrication equipment… a huge milling machine, lathe, welders, and the like. Then he rolled up his sleeves and began designing a completely new engine lubrication system for the Miura. This required designing a new engine sump pan on a CAD system, fabricating the mold for an aluminum casting, and then machining the casting for the final fitment. Achieving perfection required several different design changes (and new castings), each of which were quite expensive to implement.

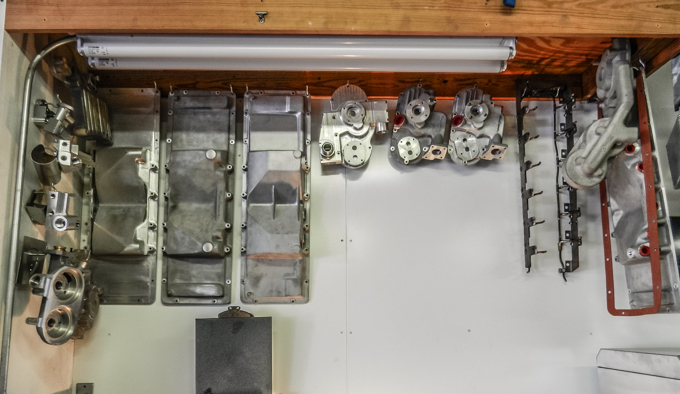

Initial prototypes for the Miura oil pan and oil pump/filter castings

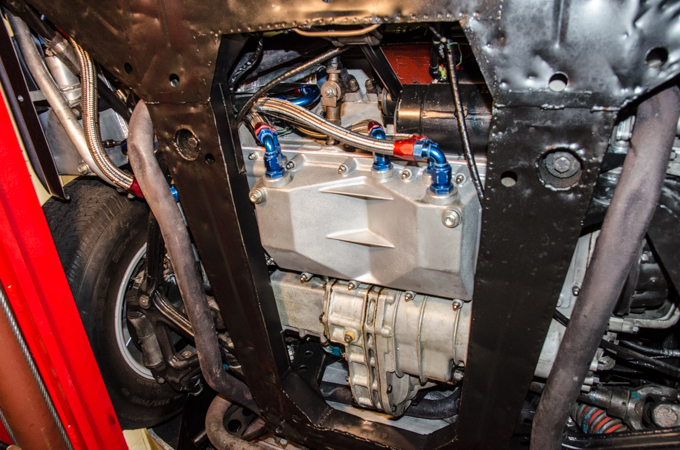

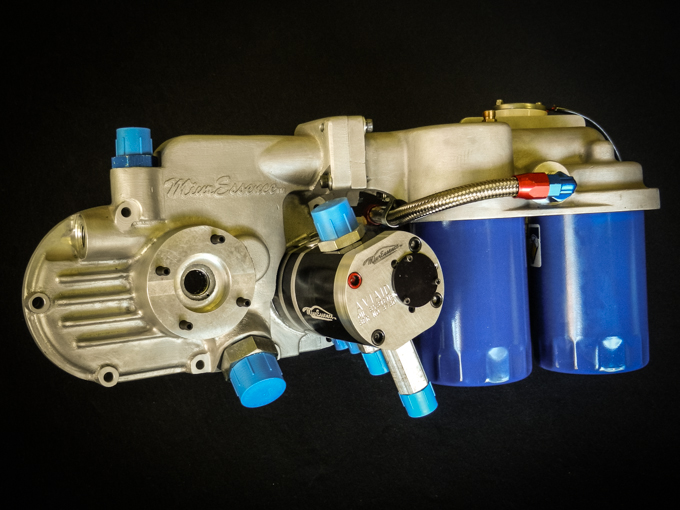

The principle enhancement to the new system was a conversion of the original “wet” sump system (and it’s inherent loss of oil pressure under hard cornering), to a “dry” sump system, requiring a specially fabricated external oil storage tank, and redesigned oil pump and filtering system.

Underneath the Miura’s engine, showing the newly designed and fitted oil pan/sump

Additionally, Scott added an electric oil “priming” pump to resolve the original engine’s tendency to operate some 5-10 seconds on startup with little or no oil pressure. The new system also included blocking off the openings between the engine and the transaxle, allowing each to have its own lubrication with appropriate oil viscosity for each. (this particular modification was one that Lamborghini addressed on its later series Miuras, in response to so many complaints and issues from the owner base)

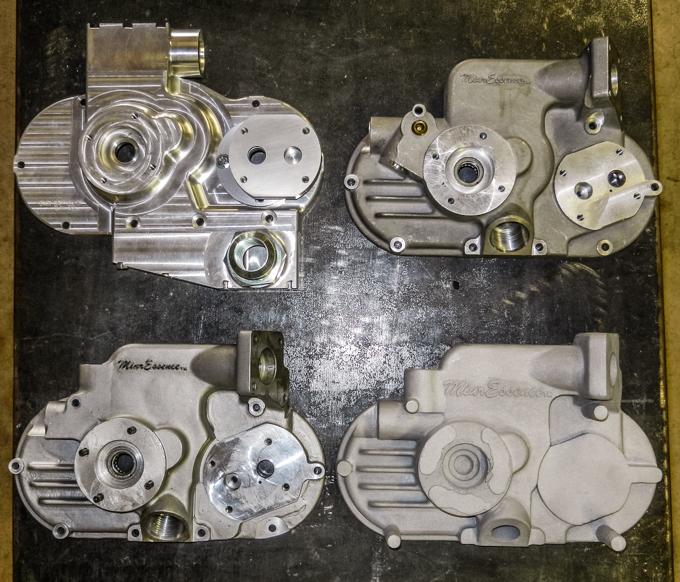

Evolution of a new part.. The upper left hand oil pump piece was machined from a single block of aluminum. The other three prototypes were cast and then machined from aluminum

Scott in front of the Lambo, holding one of the finished components of his dry sump lubrication system.

To further enhance lubrication of the cylinder walls, Scott designed and fabricated an elaborate oil spray system which kept a constant film of oil directed underneath the piston skirts.

Scott holds the first version (subsequently revised) of his cylinder wall oil misting system.

As might be imagined, completing this project posed many daunting problems. For example, Scott learned that molten aluminum will shrink upon cooling, at a predetermined rate (almost 1/4″ in the case of the oil pan’s length), so all of his casting patterns had to take that shrinkage into consideration during the design and mold-making phase. Virtually every piece of this system was designed, cast, machined, then redesigned, recast, and remachined a number of times before the final product emerged, each piece a virtual work of art in its own right, as shown below.

The oil pump/filter unit required extremely close tolerances during design and machining.

The end result of Scott Reid’s work is a beautifully integrated system that significantly enhances the reliability and durability of the Miura’s exotic engine. Scott now offers this complete system as a commercial product (along with other Miura-specific products) via his company website www.MiurEssence.com/, as well as live displays at major automotive events, such as the Pebble Beach Concours.

Of course, with a car as rare as the Miura, there is always concern over maintaining originality. With that in mind, all of Scott’s engineering enhancements for the car were designed to be a completely bolt-on upgrade. The engine can always be returned to its original configuration if desired.

The Reid’s Miura joins a few brethren in the Lambo corral at the Concorso Italiano in Monterey

But Scott is by no means a one-pony sorta guy. He proudly and regularly drives his Ferrari F355 (in a beautiful dark blue color combination), as well as a late model Corvette (once a Corvette guy, always a…).

Scott Reid’s immaculate Ferrari F355

He also recently completely a beautiful, complete nuts and bolts resto-mod restoration of a vintage C1 Corvette for a client, and will soon be taking on another such project. In between times, he hopes to soon revive his beloved ’40 Ford coupe, still sitting proudly in his garage since high school.

Scott’s high school era 1940 Ford coupe awaiting resurrection

The Miura looks good from any angle, with Scott’s beloved Ferrari F355 and 1940 Ford coupe in the background. A few vintage Honda motorcycles are lurking just out of sight!

Lamborghini Miura belongs to Scott and Tricia Reid

You can contact Scott Reid by visiting his website: www.MiurEssence.com/

Leave a reply